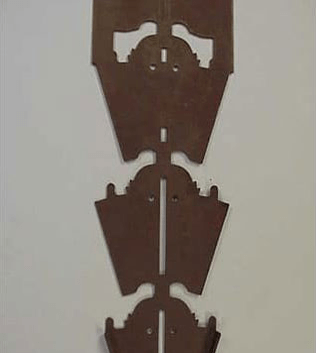

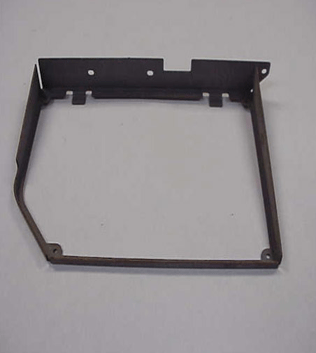

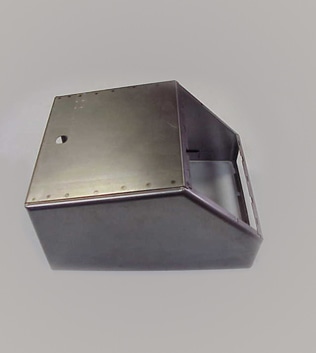

Aggressive Engineering Corp. which offers sophisticated design, machining, and precision deep draw stamping services, recently designed and manufactured the tooling and inspection fixtures for this protective, water-proof cap.

The cold-rolled steel piece protected a detonation fuse from exposure damage and accidental triggering in a munitions’ application. Our top-notch deep draw stamping, resistance spot-welding and internal threading capabilities ensured that we met our military client’s Mil-Specs requirements as well as ASTM and ANSI standards. We produced 110,000 pieces for delivery in pre-determined monthly lots.

For more detailed part specifications, please see below and contact us directly to learn more about what we can do for your organization.