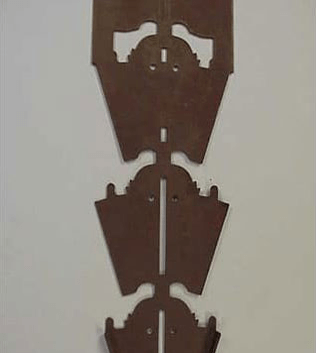

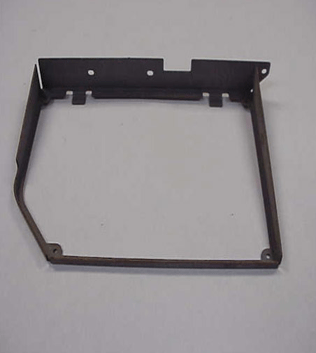

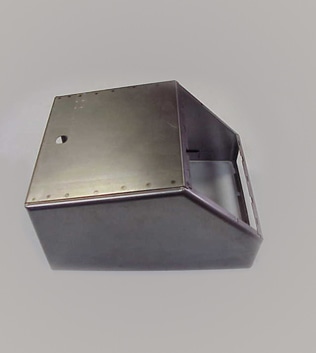

Aggressive Engineering Corp. manufactured this impact extruded aluminum missile exhaust nozzle using 6061 aluminum.

Because that nozzle would be used on a missile in a military application, the part had to meet Mil-Specs as well as the customer’s rigorous standards.

Although the component had previously been made from solid billet aluminum, we made the switch to tube aluminum in order to reduce material costs. Impact extrusion offers a fully wrought, dense, clean structure that rarely requires finishing. Its highly uniform grain alignment imparts maximum strength and toughness. As importantly, this production method also offers tight tolerances, in this instance, an impressive ±.005″. The material, in this case, 6061 aluminum also has good toughness and strength characteristics.

We produced 50,000 pieces for scheduled delivery to our aerospace customer.

If you would like to know more about how we added value to this project for our aerospace customer and ask what we could do for you, please contact us directly.