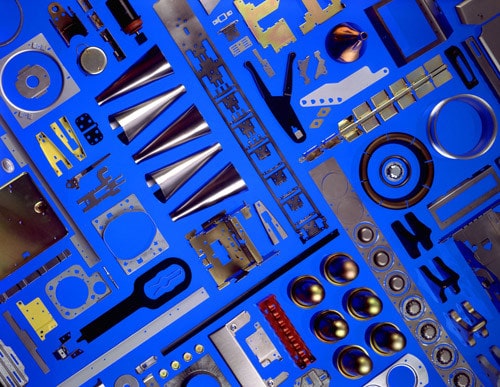

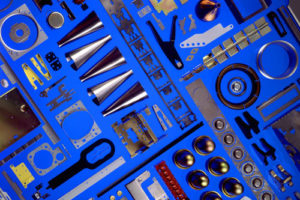

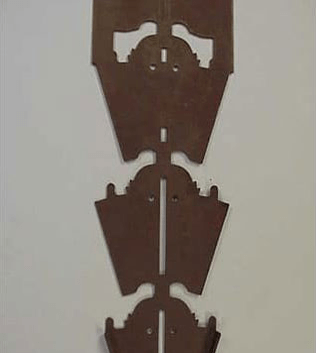

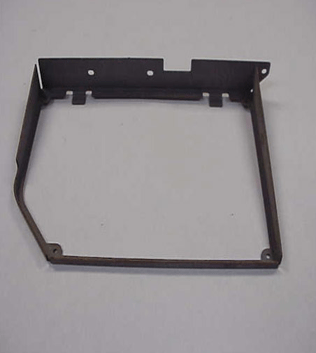

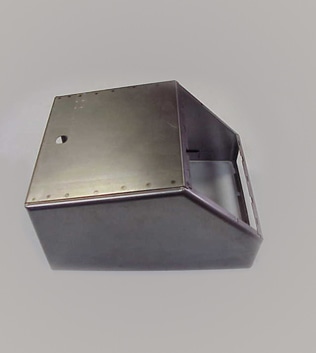

Aggressive Engineering Corp. covers all lines of metal stamping from progressive die to single hit, and from compound die to fine blanking. We excel in heavy deep draw stamping. We feature presses rated up to 400 tons, with the capability to stamp draw depths up to 18″. Minimum material thickness for this process is 0.0120″, with a maximum thickness of 0.5″. Our maximum press bed size is 48″ x 120″.

We provide metal stamping services for a wide variety of industries, including aerospace, military, medical, construction, and automotive. Just a few of the applications in which our stampings are used are electric motors, air bags, appliances, sporting goods, microelectronics, and lighting fixtures. We can work to tolerances of ±0.001″, and meet ISO, AS, and Mil-Spec compliances. We are happy to accept orders from short runs of 10 or more, up to and including millions of units.