After more than 40 years as a custom job shop specializing in custom metal stamping and deep-drawn parts, Aggressive Engineering Corp. has the technical skills and relevant experience required to satisfy demanding customers in a range of sophisticated industries.

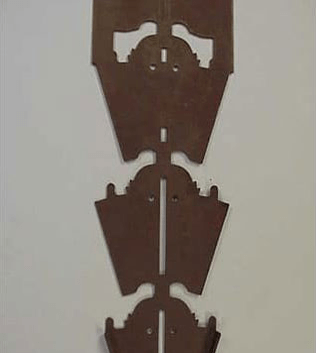

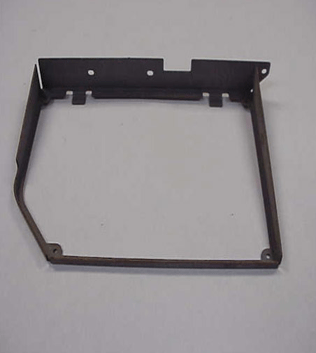

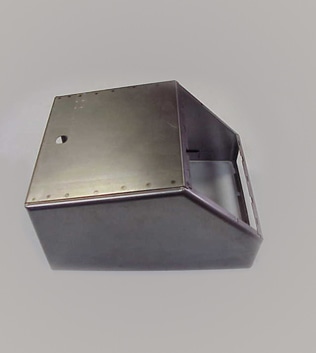

In this particular project, we collaborated with an appliance manufacturer’s engineering team to design a steel, side panel that was destined to be part of an oven. We worked from the customer’s AutoCAD tool drawings to create the design, and then performed the stamping through stage operations and hand transfer. The small spangled galvanized G40 steel we used offered the visual esthetics as well as the durability required by today’s generation of consumers.

Aggressive Engineering produced 2,500 pieces and held parts in a KanBan for the customer. You’ll find additional part specifications below and may reach Aggressive Engineering directly to find out more about us.