At Aggressive Engineering Corp., we take on projects that may appear simple but can require more know-how than might be immediately apparent. Our innovative problem-solving can deliver part redesign and process restructuring that ensure quality while manage costs.

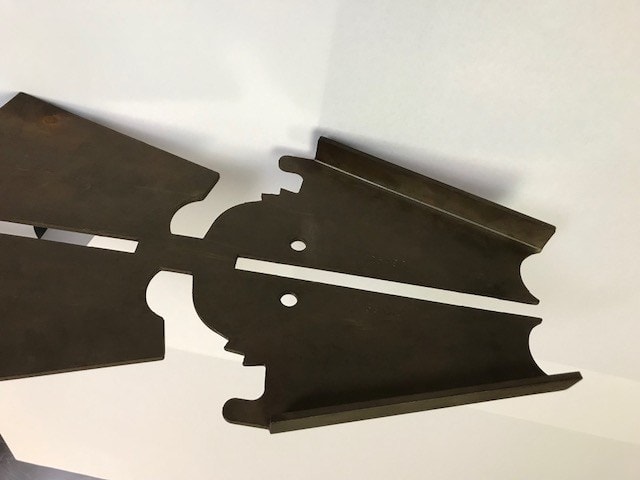

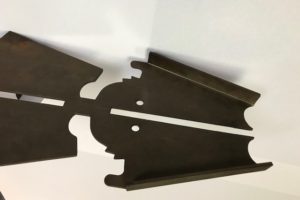

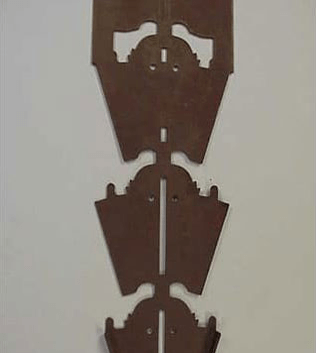

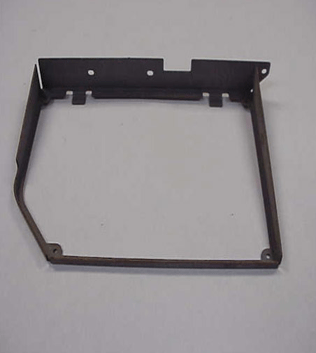

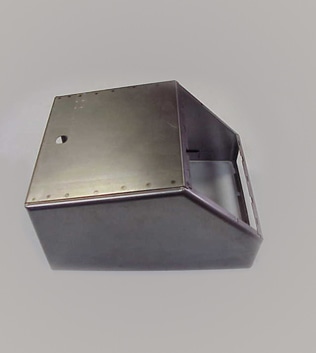

We designed and produced this progressive die stamped, left and right steel ratchet plate. Used in a treadmill application, it was designed to lift the walk/run surface of a treadmill in order to alter the incline for the exerciser. Our engineers used their design expertise to develop the AutoCAD tool drawings and to design the part separating system. We then stamped the part using progressively die-stamping. The paired parts were stamped from heavy-gauge, hot-rolled, pickled, and oiled (HRP & O) steel. Upon completion of the scheduled weekly deliveries, we had provided 75,000 parts to our health and fitness industry client.

For more information on this project and our capabilities, please contact us directly.