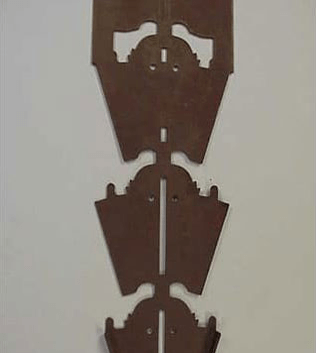

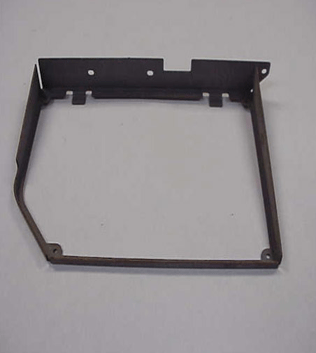

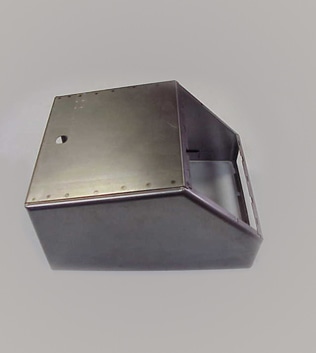

Aggressive Engineering Corp. experienced design team developed the design and drawings for this quality die stamped, steel projector mounting frame. The choice of electro-galvanized steel ensures the frame has a smooth, attractive, and durable surface that is also corrosion-resistant. At our 21,000 sq. ft. plant, we manufactured 75,000 pieces for just-in-time delivery to our electronics industry customer.

As a modern, forward-thinking company, we leverage technology to boost efficiency and quality whenever possible, but take just as much pride in our ability to effectively communicate and collaborate with our clients. For more information about this project and on how we can design and manufacture the product that best meets your needs, please contact us directly.