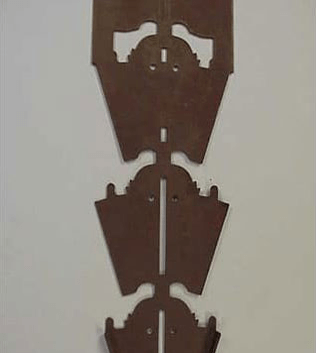

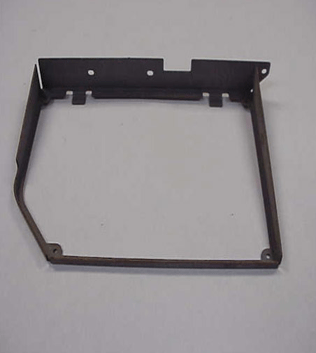

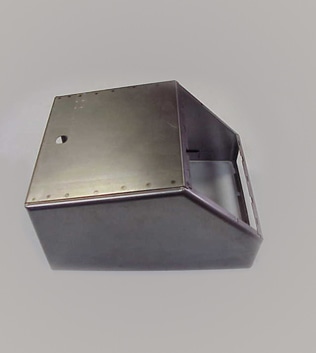

At Aggressive Engineering Corp., we provide custom deep draw stamping which allows the highly cost-effective, high-volume production of seamless circular parts. Our experienced design engineering team created the AutoCAD die drawings and the custom inspection fixtures. After stamping, the parts were fusion-welded to create a ultra-violet light chamber, intended for a residential water purification and filtration device. We used 304L stainless steel and employed a multi-stage deep draw stamping processes, and special die inserts to produce a scar- and scratch-free surface. We effectively produced 1,200,000 parts for just-in-time (JIT) delivery to our client.

We are ISO 9000 certified and in today’s competitive, sophisticated environment, we support our commitment to lean, quality-driven manufacturing through our use of Six Sigma management strategies and systems as well as Statistical Process Control documentation.

For more information on our deep draw stamping services and Aggressive Engineering, please see below or contact us directly.