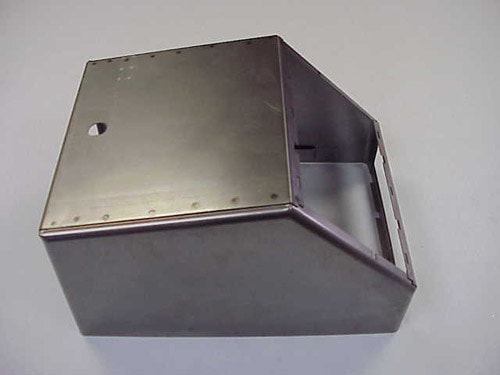

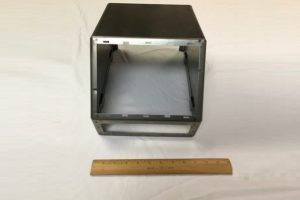

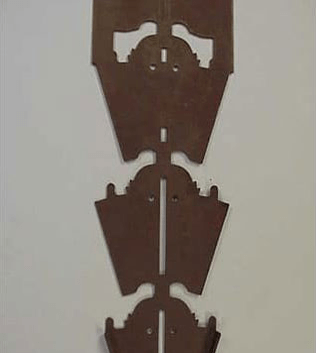

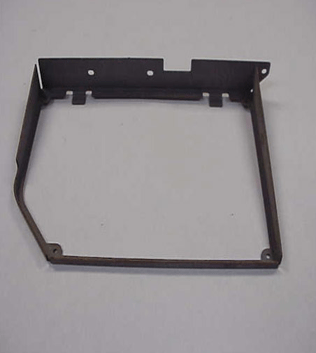

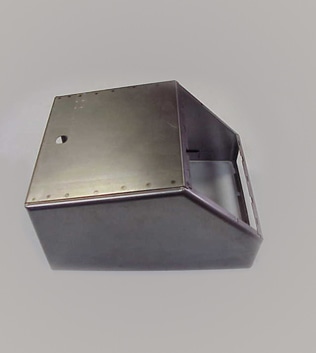

Aggressive Engineering Corp. designed the die and assembly fixtures for this custom metal stamped, cold rolled steel cabinet that would house a time-keeping clock. We stamped the piece in a single-stage that included blanking and forming. In addition, we provided the spot welding and assembly that were required. Custom metal stamping is a precise and highly cost-effective process for the mass production of everything from relatively simple to more intricate, complex parts.

Cold rolled steel offers a number of advantages over its hot rolled counterparts, for instance, creating a better finish and increasing the yield strength, particularly where the metal has been bent by folding. Cross-sectional shapes can be formed to close tolerances and consistently repeated. We metal stamped 2,500 pieces for our labor accounting industry customer.

We would be happy to provide more information on this project and explain what the Aggressive Engineering team could do for you.