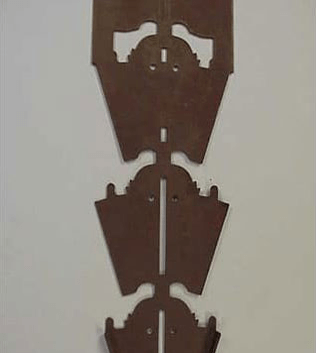

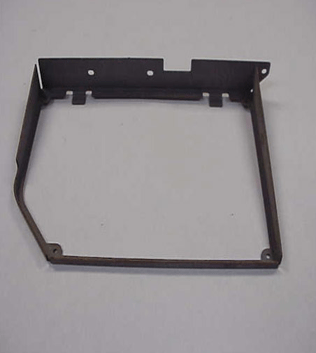

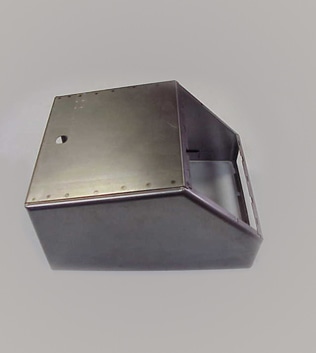

In Anaheim, California, Aggressive Engineering Corp. compound die-stamped this dry-erase board, which allowed us to perform more than one process during the press cycle. In short, we were able to perform multiple cuts or punches in a single stroke rather than several. We turn to compound die-stamping when we want to stamp medium to high-volume parts while managing die and labor costs.

In Anaheim, California, Aggressive Engineering Corp. compound die-stamped this dry-erase board, which allowed us to perform more than one process during the press cycle. In short, we were able to perform multiple cuts or punches in a single stroke rather than several. We turn to compound die-stamping when we want to stamp medium to high-volume parts while managing die and labor costs.

At Aggressive Engineering, we know our materials – that’s why we selected MDF when approached about compound die-stamping a dry-erase board. We knew it would be used as a training aid in the fitness and sports industry, which made a smooth surface, strength, moisture- and warp-resistance highly desirable characteristics.

We produced 50,000 pieces for just-in-time delivery to our sports and entertainment client.

In order to learn more about this project and inquire about what we could do for you, please contact us directly.