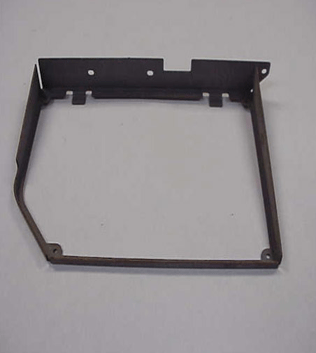

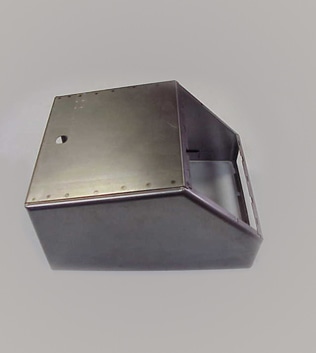

A water heater manufacturer was in need of a deep drawn stamping service that could create a galvanized steel enclosure for one of their water heater products. The enclosure’s previous design required that RTV silicone be applied to seal the lid, the process was both time-consuming and messy. In view of the high volume that the product required, this approach was proving particularly costly and inefficient in the long-term. When our client decided to rectify this assembly challenge, they turned to us for a solution. We collaborated with them to develop a design that incorporated an O-ring and clamp seal design.

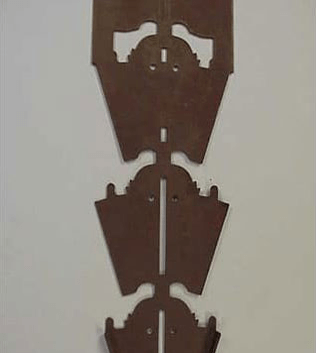

Aggressive Engineering offered design assistance as well as production and assembly insights while leveraging our AutoCAD and reverse engineering expertise. In production, our deep draw stamping processes included blanking, trimming, curling and forming. Our lean and efficient deep draw stamping operation produced 50,000 rust-resistant lower enclosures in electro-galvanized steel.

To learn more about what we can do to solve your design and manufacturing challenges, please contact us directly.